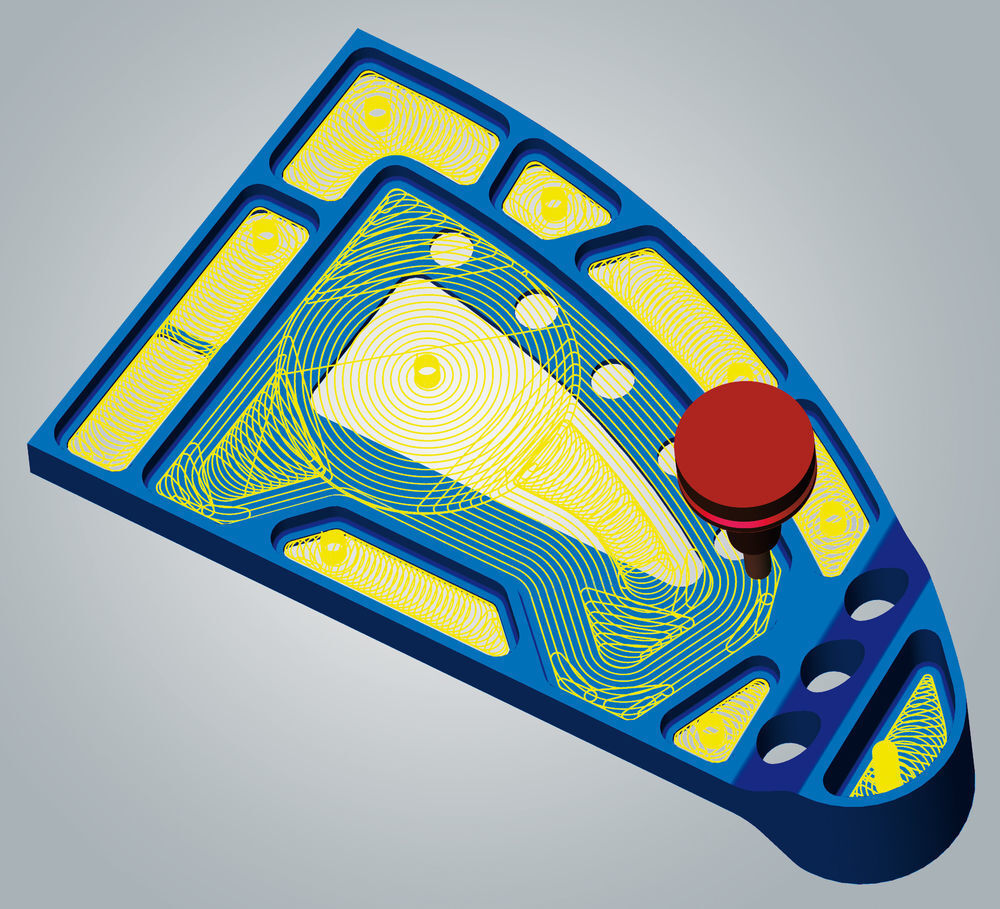

Many years ago, these enhancements would focus solely on better toolpaths. Levine: Cycle-time improvements are clearly important to end-user return on investment and productivity. ME: How critical is speeding key machining cycles, like roughing, in today’s production environment? Some of the new or improved topics include a T-slot geometry feature to augment the T-slot on 3D model cutting strategy, automated creation of reference geometry for swarf milling, enhancement to 3D-optimized roughing to modify feed rates and adjust step-down depending on stock conditions, and five-axis rework enhancement to change feed rates based on conditions with ‘trim to model.’ This release covers 2.5D through five-axis milling, mill-turn and new modules such as the hyperCAD-S Electrode module.

Manufacturing Engineering: What’s new in your latest hyperMill CAM software update?Īlan Levine: As with all Open Mind upgrade releases, hyperMill 2017.2 has a broad range of new technologies and enhancements.

0 kommentar(er)

0 kommentar(er)